Using smart technology to update your electronic products

Is your business struggling to keep up-to-date with the connected world? Do you have a product that would benefit from becoming a smart device? In this blog, we’ll look at how industry leaders can ‘digitise’ their products using hardware design and software development and bring seamless connectivity to their products.

Touché Technology has more than ten years’ experience in helping technical directors improve electronic products and help them drive their businesses forward. This could include designing new products or giving old products a new lease of life by making them wireless or connecting them to apps.

We’ll explore key themes that impact the world of product development:

- Simple definitions of the ‘Internet of Things’ and ‘smart technology’ and their role in making products wireless.

- Why wireless connectivity is essential for people who are responsible for managing a company’s technological requirements.

- Case study: how we updated The Fire Beam Company’s existing product and introduced app usability.

- How we use Bluetooth Low Energy to enable wireless connectivity.

- Touché Technology’s step-by-step process of upgrading a product to make it wireless.

Smart technology, the Internet of Things, Bluetooth, wireless… We all know these terms, but what are they and how can they make a difference to your business?

It’s particularly important for employees to understand these phrases as they can’t afford to end up with the wrong solution for their product. We thought it would help to explain these terms in more detail.

What is the ‘Internet of Things’?

The ‘Internet of Things’ (IoT) is a term for using the internet to connect physical objects and making them connect and communicate to collect data. Back in 2008, there were already more objects connected to the Internet than people. In 2023, there are approximately 15.14 billion products connected to IoT devices. This figure is expected to almost double to 29.42 billion by 2030.

A common IoT set up often includes hardware, a software system and some kind of application, with something like Bluetooth acting as the communication layer. Machines can exchange data and information by using built-in chips, software and sensors. The IoT then coordinates this data and turns it into information that users can understand. Objects can then perform tasks and make decisions without the need for a human being.

These objects could be everyday devices such as smartphones, appliances, vehicles or industrial machinery. The IoT increases efficiency, improves health and safety, and creates better user experiences.

What is ‘smart technology’?

What makes a technology ‘smart’ is its ability to communicate and work with other networked technologies without the need for wires. It enables devices, systems and applications to use Artificial Intelligence (AI), internet connectivity and other advanced technology to enhance a product’s functionality.

Both Near-Field Communication (NFC) and Bluetooth Low Energy are key enablers of the IoT.

The importance of wireless technology for electronic product design in the industrial sector

‘Industry 4.0’, the ‘Fourth Industrial Revolution’, is revolutionising the way manufacturers are operating their businesses. The rapid development of smart factories, AI, machine-to-machine technology and the IoT are transforming industrial sectors.

Wireless connectivity has become an expected feature in many industrial and consumer products. Developing a wireless product can help meet market demands and align with people’s expectations of seamless and connected experiences.

Here are some of the benefits of companies enabling wireless technology:

- Wireless technology enhances user experience and expands the capabilities of devices and systems, such as remote monitoring and control.

- It limits the need for physical cables and wired connections, which reduces the risk of downtime and costs.

- Products can be expanded as they won’t need to have a wired connection.

- Many products can connect to other devices using the IoT, which means your product could integrate into larger networks. They integrate well with emerging technologies such as cloud computing and AI.

- Some wireless products can be managed remotely, so they can be used from a different location or over the internet. This creates more freedom of movement for staff as they don’t have to be tethered to one location.

How we upgrade electronic products and make them wireless

Our specialist team of engineers has the knowledge and experience to design innovative solutions for challenging and often ground-breaking requirements. Generally speaking, upgrading a product to make it wireless involves adding wireless communication capabilities and removing any wired connections. We then leverage the power of the IoT to connect an app with a physical device. Whether it’s through Bluetooth Low Energy, NFC, or WiFi, we ensure seamless communication between apps and the devices they control.

Bringing wireless connectivity to industrial products enables technological directors to future proof their products. Wireless connectivity makes workflow considerably more efficient and provides simple convenience for engineers and staff – this can often be much cheaper to install.

Case study: connecting The Fire Beam Company’s fire alarm system to an app and making it wireless

The client

ConvergePD, which manages and resources product development, commissioned Touché Technology and app design specialists Gooii to upgrade The Fire Beam Company’s ‘Fire Beam’ system.

The Fire Beam Company specialises in manufacturing optical smoke detectors for engineers to install, configure, and operate in large commercial buildings such as warehouses.

The brief

Fire Beam’s customers install and maintain fire detection systems. Without wireless control they have to fit an expensive control box to each device to allow it to be configured and checked. The client wanted an app and a wireless solution to control the devices, rather than a control box, as it would make it much cheaper to install and more convenient for the engineers.

Electronic product design: Touché Technology’s project deliverables

- New Bluetooth hardware and firmware that connects to an app

- Updated Fire Beam hardware with Bluetooth connectivity

Collaborations

Touché Technology worked with app development agency Gooii, which designed the app that controls the new Fire Beam BLUE devices. We also worked closely with ConvergePD to fully define the requirements.

Jon Ben, Director, ConvergePD Limited: “We worked closely together with Touché over the last 2-3 years on a safety-critical project. This relied upon Touché’s deep knowledge in the field of Bluetooth, as well as for general software and electronics capability. Touché has its own network of trusted suppliers that also complement our projects and bring good value to our clients. ConvergePD particularly value Touché’s quality of work, relationship and responsiveness. We hope to have the opportunity to work again on other such specialist projects.

“ConvergePD Ltd provides a complete product development service to its clients in life-safety and industrial markets. To be able to achieve that, we partner with high quality and reliable specialist suppliers in the fields of electronics and software.”

What we did

Touché Technology upgraded the Fire Beam’s hardware to add Bluetooth Low Energy technology (more on this later) and solve a number of manufacturing issues.

The product was given a new lease of life by updating it with modern technology using the IoT. This created an innovative solution to a challenging problem and revolutionised conventional beam detectors for the company.

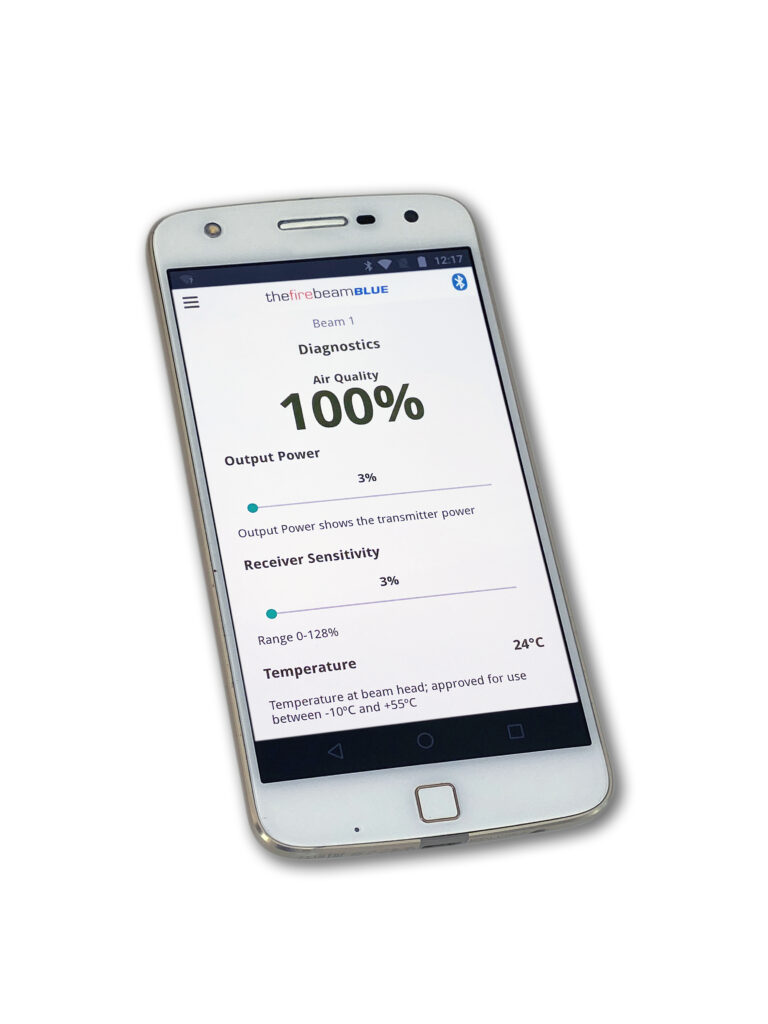

The new hardware allows engineers to control beam detectors through smartphones or tablets.

We worked with Gooii to create an app that controls each detector and connected this to the hardware.

Designed primarily for warehouses or buildings with high ceilings, the Fire Beam BLUE is an optical beam smoke detector that plays a crucial role in fire safety. However, once these detectors are installed, their location often makes them extremely difficult to access. Fortunately, the Fire Beam BLUE app eliminates this challenge by leveraging Bluetooth Low Energy connectivity. This enables engineers to effortlessly set up and configure the device, similar to the convenience of connecting to thermostats using smart home apps.

How the wireless Fire Beam system works

The smoke detector emits an infrared beam to a prism positioned at the opposite end of a room. If this beam is disrupted by the presence of smoke, it triggers a fire alarm, which can be conveniently configured through the Fire Beam BLUE app. You simply connect the hardware to each beam using Bluetooth technology, so you don’t need a phone signal or an internet connection.

What is Bluetooth Low Energy?

Many of us know that Bluetooth is a wireless communication technology that allows devices to communicate with each other through radio waves.

Compared to classic Bluetooth, Bluetooth Low Energy (BLE), provides low-power consumption and reduced cost. It is commonly used in the IoT devices.

BLE is designed to provide energy-efficient connectivity for devices that use small batteries for long periods of time, as it stays in ‘sleep mode’ until a connection is initiated. This is ideal for applications that periodically exchange data. This technology is most commonly used for heart-rate monitors, locks, smart watches and wearable gadgets. Most operating systems will support BLE, which makes it easier for us to create apps that connect with products.

As well as Fire Beam, we have also used BLE technology for access control products such as locks. Our team often advise access control companies on the application of BLE to change the way users interact with security products.

Touché Technology has also used BLE to develop a dynamic, fast-paced music-mixing game called DropMix™, for which we worked hard to solve the card-to-board-to-app communications requirements.

The step-by-step process of upgrading and digitising an existing product

When developing a new product or updating an old one to bring it up-to-date, it is important to go through the below steps to ensure you have everything covered. This helps to understand what you actually need, rather than what you think you or your market needs. Touché Technology can help you with this process. We’ve provided a general overview of our product development process, which enables us to digitise existing products.

1. Conduct market research

The Fire Beam Company spoke to its customers to understand what they liked and disliked about the existing Fire Beam BLUE product – asking what caused them issues and whether these were to do with installation time, cost or difficulty using the product. They also asked what features would make them more likely to buy the product.

Armed with invaluable customer feedback and new requirements, they asked us to upgrade the product with a detailed brief.

2. Create a detailed specification

We worked closely with Gooii and ConvergePD to create a detailed specification of what needed to be developed. This included details about the user interface, features, certification requirements, electronic and electrical requirements and mechanical details.

The process enables the customer to focus their attention on the product’s finer details. These small details are often the most important changes that can lead to successful products.

3. Write a detailed framework

We put together a detailed framework that we will test against when we get to the prototype stage. This ensures that any future changes are always matched to the original specification to ensure the product is doing what we intended it to do.

4. Electronics design and development

The bulk of the work is done at this stage.

- Our specialist team designs the device’s electronics schematics, which are the circuit diagrams.

- Design and route the Printed Circuit Board (PCB) using CAD tools.

- Write the firmware code using a variety of different Integrated Development Environments, which are different types of software suites or programming tools. The firmware (or ‘software’), allows the hardware to communicate with the operating system and do what is requested by the user.

- If the project needs any mechanical design, this would also be performed using 3D CAD tools.

We closely interact with our customer’s team, particularly the mechanical or product design engineers. Our designs must fit inside their device and we often have to work within very tight space constraints.

Touché Technology often work alongside third-party suppliers who are developing other parts of the solution. With the Fire Beam BLUE solution, we worked closely with Gooii to create the app that connected to the hardware we designed.

5. Assembly of prototypes

Once the electronics design work is complete, we send the manufacturing data to assembly companies to make the PCBs. They will assemble components onto them, turning them into complete units. We use these as prototypes to do firmware development and perform testing.

6. Testing against the original specification

Product development is an evolutionary process and the first prototype is rarely identical to the final product.

The testing stage involves making sure that the solution does everything that the specification requires of it. We make sure there are no bugs or other issues and ensure the product is reliable and robust.

At this stage we may go back to the design and make revisions to fix any issues and make improvements.

7. Customer acceptance testing

As soon as we’re happy that the solution works as required and expected, the customer must also test it for themselves.

The customer might find that things can be improved or enhanced. We might revisit the design and make new prototypes that feed into the final product.

8. Release to manufacture

When the prototypes are finalised and the customer is ready for the product to go into production, the data is collated and sent to a manufacturer. The manufacturer will test each item to ensure it works correctly. This is often referred to as the ‘Design For Manufacture’ process, when our product design is translated into a set of data that can be used to make things. It will also define how the product should be tested.

Wireless technology provides greater flexibility and scalability compared to wired solutions. It allows for easy integration with existing systems and infrastructure without the need for extensive wiring installations. Products can be easily added, expanded, or reconfigured as per the user’s needs, providing a more adaptable and scalable solution.

If you’d like to speak to us about upgrading your product and introduce wireless connectivity into your business, please get in touch.